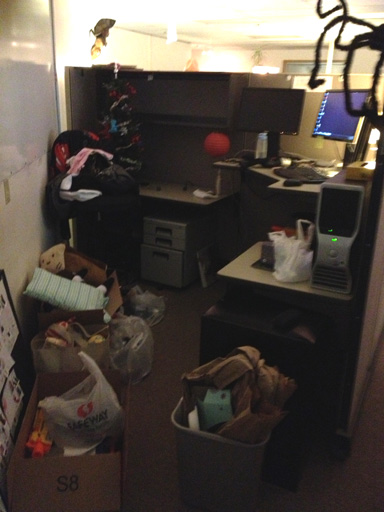

My last workplace had a nice perk: a standing desk option! In the midst of layoff-day packing up, I grabbed a photo to help me remember how nice this setup was:

The question that’s been on my mind since then is, of course, How can I bring home the awesomeness of standing up all day?

Other/better articles have already covered in depth the benefits (and risks) of standing, but my motivation is simple: it just feels better. Sitting 8-10 hours makes my butt and legs sore, makes me have to exercise a lot more to feel tired by the end of the day, and just feels slouchy and lazy. I did not adapt to sitting again, so I set out to build my own DIY standing desk.

My Current Desk

My current desk is an IKEA GALANT, with two additional sections attached the left side to widen it. Someone already modded/IKEA-hacked this desk in its previous life, but this same desk plus extensions can still be found at IKEA as of 2013.

The simplest/most obvious solution to elevate this desk to standing height by swapping out its existing legs in favor of legs that would extend to at least 41”, which is the distance between the floor and my elbow. Fortunately, IKEA provides such legs, the VIKA BYSKE, which go to a maximum of 42”. (This max-height works for me, but not for my husband who will need a height of 47” in his own standing desk.)

Anyway, we picked up the 5 legs from IKEA for $30 each and got to work on attaching them.

Three Complications

- VIKA BYSKE legs come with their own “bracket”, they don’t screw into a separate bracket like other legs of this style. This meant we had to remove the existing brackets from the table, even though they were IKEA and look exactly the same

- IKEA has slightly changed the size/arrangement of screw holes on its leg brackets, so these new legs with their fused-on brackets couldn’t re-use the existing holes from the previous brackets

- VIKA BYSKE legs are SUPER ANNOYING to extend. It took my husband and I about 20 minutes of wrist-agony to twist all five legs to 41”.

Some shots of the underside of the desk:

Attaching Longer Legs

We took everything off the desk and flipped it upside down to attach the legs. Once the new legs were on and we stood it back up, several new problems were revealed:

- My monitors are too low by at least 6 inches

- The desk is WOBBLY

I first took a trip to Staples where I was disappointed by their selection of monitor stands. They aren’t tall enough, and they didn’t seem robust enough the widescreens. Ultimately, just to make the desk usable in the meantime, I balanced a book shelf over four small paint cans and put the center monitor onto that. This disrupts my usual workflow, though, as using the other two monitors is rather unpleasant on my neck/upper back. But I think I could build or find something with a bit more looking, so I’m not particularly worried about this problem.

The wobbly feeling has me much more concerned.

We could attach more legs, but will it be enough? The one leg at left is definitely underpowered for the kind of support it needs to provide now.

Anchoring to the Wall

I was wandering around Home Depot when inspiration struck: shelf brackets! Two shelf brackets and a about 20 minutes of EZ-Anchors and drilling later, the desk was anchored to the wall and completely stabilized. I anchored it 1 inch off the wall to leave room for curtains and wires. The desk is rock solid now, woohoo!

Project Cost

IKEA GALANT desktop – free (picked it up off the curb)

5 VIKA BYSKE legs – $125 ($25/each)

2 heavy duty shelf brackets – $12

TOTAL: $137

What’s Next?

With that resolved, it’s time to move onto a more challenging project. Next up: I’m going to build one for my husband, who is 6’4” and too tall for the solution we used for mine.

Some “ready made” standing desks I’ve found online go high enough for him, but they have many shortcomings:

- Insufficient monitor space (most seem built for one monitor, tops)

- Too expensive (largely thanks to features we don’t need, like electrically powered up/down)

- Too small in general – no one makes a standing corner desk… but I will be the first. >:)

Update: We built it! Check out my husband’s super tall standing desk right here.