We have absolutely no budget for a bathroom remodel, so I’m going into DIY mode to refinish this vanity using leftover supplies from my kitchen cabinet refinishing project. Due mostly to dry times, refinishing my master bathroom vanity was about a five day project with about 3-5 hours a day of work each day except the first (which was super quick).

In this series of posts, I’ll walk you through all the steps of refinishing a wood bathroom vanity:

- Stripping the wood varnish (or paint, if yours is painted)

- Sanding for a nice smooth surface

- Priming so the enamel sticks

- Painting a durable enamel

Let’s begin!

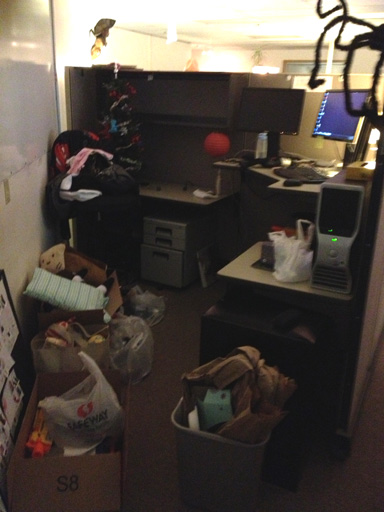

Empty the Bathroom

The very first step is to remove everything that isn’t related to this home improvement project. It’s going to get extremely messy and dusty in here as we strip varnish and sand the cabinet faces.

Unless, of course, you can take your vanity or cabinet doors outside, which I couldn’t thanks to near constant rain during the week I spent refinishing this vanity.

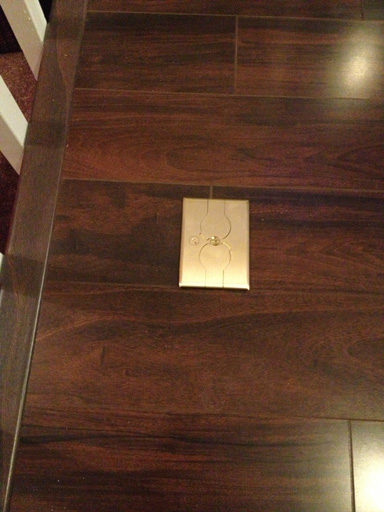

Remove Existing Hardware

Removing the cabinet hardware (knobs and such) is also essential – painting around things is bad. Very bad.

Apply Stripping Gel

CitriStrip worked very well on my kitchen cabinet project, so I’m using it again on this one. One bottle has been enough for both my kitchen and now this bathroom.

Citristrip smells like an orange Popsicle.

Since all I’m removing here in the bathroom is a thin layer of varnish, I don’t need to lay the Citristrip on too thick: just a thin but consistent layer on every wood surface ought to do it. For this step I use a cheap plastic paint brush and a few paper towels.

I’ll come back in 24 hours to scrape and sand the peeling varnish.

Hardware off, Citristrip on